Process & Provenance

From Forest to Fitted Joinery

Designed to Outlive the Trend Cycle.

Kenton Jones designs and manufactures bespoke kitchens and joinery in-house, with full control of materials, tolerances and installation. For clients who care about heritage, longevity and quiet luxury, our process is built around certainty: measured design, engineered manufacture and finishes that mature beautifully over time.

Our clients are not chasing show-home fashion. They want cabinetry that sits naturally within the architecture, materials that age well and joinery that still feels right in ten, twenty, thirty years.

That outcome depends on more than craftsmanship. It depends on how the work is specified, engineered and controlled from the beginning. That is why we combine design discipline, in-house manufacturing and documented provenance.

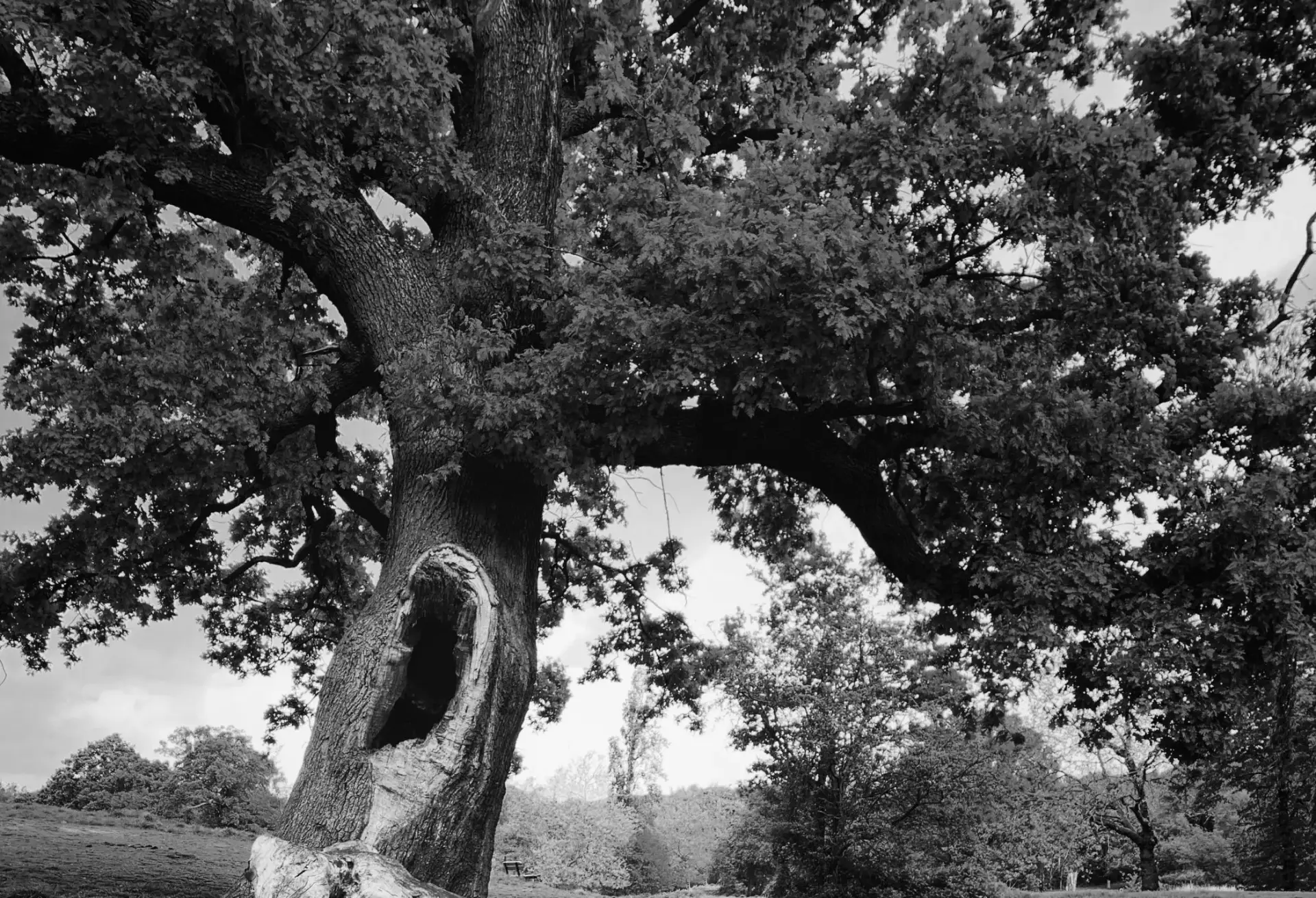

PROVENANCE

Materials you can place

with confidence

We source timber with traceable provenance, selecting boards for stability, grain and suitability to the environment they will live in. For many clients, provenance is peace of mind: knowing what the material is, where it came from, and why it is right for the job.

Where appropriate, we can also incorporate timber from a client’s own land, subject to assessment and seasoning requirements. In every case, the goal is the same: joinery that behaves properly over decades, not seasons.

Traceable UK-sourced timber

Selected for stability, not speed

Documented specification from start to install

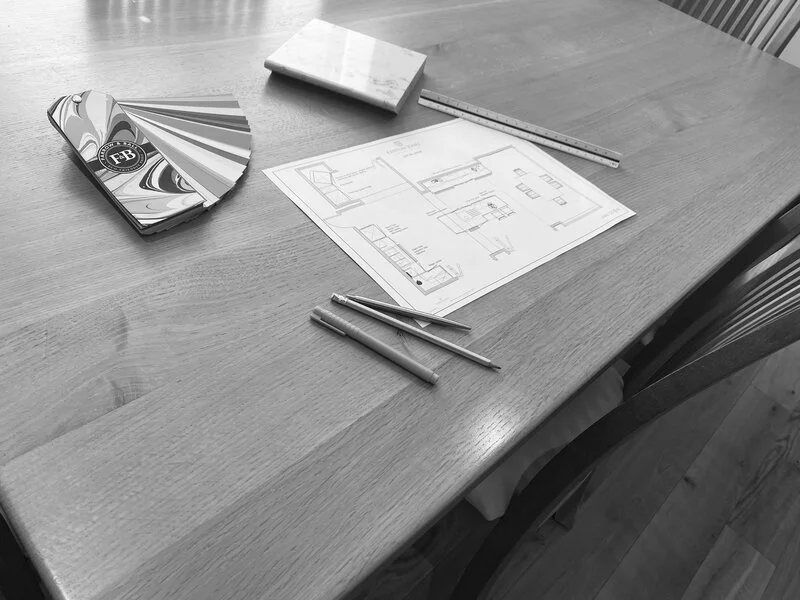

PROJECT JOURNEY

The Kenton Jones Process

Phase I

BRIEFING AND ARCHITECTURAL CONTEXT

We begin with how you live, how the house behaves, and what must be protected. For heritage properties, we look beyond the kitchen to sightlines, proportions, existing joinery, thresholds, and the character that should remain untouched. The outcome is a clear design direction anchored to the architecture, not fashion.

Output: A clear design direction anchored to the architecture, not fashion.

Phase II

MEASURED SURVEY AND SITE REALITIES

Old houses rarely follow straight lines. We carry out a measured survey to capture walls, levels, openings, beams, and services as they truly are. This is where risk is removed: we design to the building you have, accounting for irregularities so the finished joinery sits naturally, with consistent reveals and clean junctions.

Output: A verified survey that removes assumptions and protects fit in an irregular building.

Phase III

LAYOUT, FLOW AND PROPORTION

With the context confirmed, we develop the plan around movement, storage logic, and how the room will be used day to day. We balance function with restraint, ensuring the cabinetry feels integrated rather than imposed. Every decision is made with longevity in mind: what will still feel right in twenty years.

Output: A resolved layout built around flow, proportion, and long term daily use.

Phase IV

TECHNICAL DESIGN AND SPECIFICATION

Before anything is made, the design is technically resolved. Appliances, worktops, ventilation, lighting, electrics, plumbing, and tolerances are coordinated and signed off. This is the point where uncertainty ends. It prevents compromises on site and protects the quality of the finished installation, particularly in complex, older buildings.

Output: A fully coordinated technical specification, eliminating on site compromise.

Phase V

MATERIALS, FINISH AND PROVENANCE

We specify materials for stability, touch, and how they will mature over time. Timber and finishes are selected with documented provenance and suitability in mind, rather than trends. The aim is quiet luxury: surfaces that wear gracefully, joinery that belongs to the house, and detailing that improves with age rather than dating quickly.

Output: Materials and finishes chosen for provenance, stability, and graceful ageing.

Phase VI

IN HOUSE MANUFACTURE AND CONTROLLED TOLERANCES

Manufacture takes place in house, where we control quality, consistency, and fit. This is what separates a workshop made kitchen from an assembled one. Joinery is built to the signed-off specification, checked as it progresses, and prepared for a predictable installation. The result is precision without fuss, and craftsmanship you can measure.

Output: In house manufacture to controlled tolerances for predictable, precise installation.

Phase VII

INSTALLATION, FINISHING AND AFTERCARE

Our installation team fits the joinery with the same discipline used in design and manufacture. We protect the home, manage details on site, and complete finishing touches so everything feels settled, not newly imposed. After handover, we remain available for adjustment and future changes, ensuring the kitchen continues to serve the house as it evolves.

Output: Disciplined installation, refined finishing, and ongoing aftercare as the home evolves.

TRUSTED CERTAINTY

One team. One line of responsibility.

A high-quality kitchen depends on more than joinery. It relies on correct sequencing, accurate services positions, and coordinated integration of appliances, worktops, ventilation and lighting. We take responsibility for the kitchen as a complete system, so you are not left managing multiple trades to make it work.

Cabinetry design, manufacture, finishing and installation under one roof

Clear first-fix requirements issued early for electrics, plumbing and ventilation

Coordination for worktop templating and fitting around the cabinetry

Appliance integration planning so everything sits correctly and functions as intended

On-site detailing, alignment and finishing so the kitchen feels settled, not assembled

Aftercare and future adjustments as the home evolves

WHAT WE DO

Five decades of master craftsmanship, delivered with certainty

Drawing on skills passed down through two generations Kenton Jones designs, manufactures and installs bespoke kitchens and joinery in-house, with full control of materials, tolerances and finish. That depth of capability is why discerning clients trust us with complex homes and long-term projects, where certainty and longevity matter as much as beauty.

Let's bring your project to life

Handcrafted in Welshpool, Mid Wales, with our showroom in Shrewsbury covering Shropshire and Cheshire, our master craftsmen will bring the soul of your home to life. Book your consultation and start creating a unique space that sits in harmony with your home.

FAQ: PROCESS & PROVENANCE

Frequently Asked Questions

Do you design bespoke kitchens for period and heritage homes?

Yes. We specialise in bespoke kitchens for period homes, where walls, floors and openings are rarely standard. Our process is built around measured design, controlled manufacture and a disciplined installation so the joinery looks like it belongs to the house.

How do you deal with uneven walls, out-of-square rooms and old-house displacement?

We design to the building as it exists. A measured survey captures levels, openings, beams and services, then we resolve tolerances before manufacture so the finished cabinetry sits naturally with consistent reveals and clean junctions.

Who coordinates electrics, plumbing, ventilation, lighting and appliances?

Ideally, we coordinate the full kitchen scope so everything is designed and delivered as one system. Where other trades are appointed, we work closely with them and your project team, providing clear first-fix requirements and technical guidance to ensure services, lighting and appliance integration align precisely with the cabinetry and installation programme.

What does “provenance” mean in practice?

It means we can tell you what the timber is, where it came from and why it is suitable for the environment it will live in. Where appropriate, we use UK-sourced timber with traceable origins and keep the specification documented from start to installation.

Can you use timber from my own land?

Sometimes, yes. Subject to assessment and seasoning requirements, we can incorporate timber from a client’s own land. We will advise what is suitable for long-term stability and what should not be used for cabinetry.

What makes you different from a kitchen retailer or a fitter?

Retailers assemble, fitters install. We design, manufacture and install in-house, controlling materials, tolerances and finish. That removes uncertainty, reduces site compromises and delivers a calmer, more exact result in complex homes.

Do you provide aftercare once the kitchen is installed?

Yes. We remain available for adjustment and future changes as the home evolves. The aim is joinery that settles properly in the building, supported by a team that knows the project end-to-end.